All About The Process

Involving YOU in every step!

The Design

At the heart of our custom jewelry creation process lies the artistry of design and the precision of modern technology. It all begins with a spark of inspiration, whether it's a client's vision or our own creative collaboration. Our skilled designer meticulously crafts each piece, paying close attention to every detail, from the overall aesthetic to the intricacies of each element.

Once the design concept is honed in, we seamlessly transition into the realm of CAD (Computer-Aided Design). Here, our designer leverage cutting-edge software to translate you visions into digital renderings with unparalleled accuracy. This rendering offers a lifelike preview of the final piece, allowing customers to visualize how it will look and feel. At this crucial stage, customers have the opportunity to review the design and make any desired modifications. Whether it's adjusting the size, refining details, or exploring alternative elements, we work closely with customers to ensure their vision is brought to life exactly as they imagined. Once the design is approved, we proceed to the prototype stage, confident that it will exceed expectations.

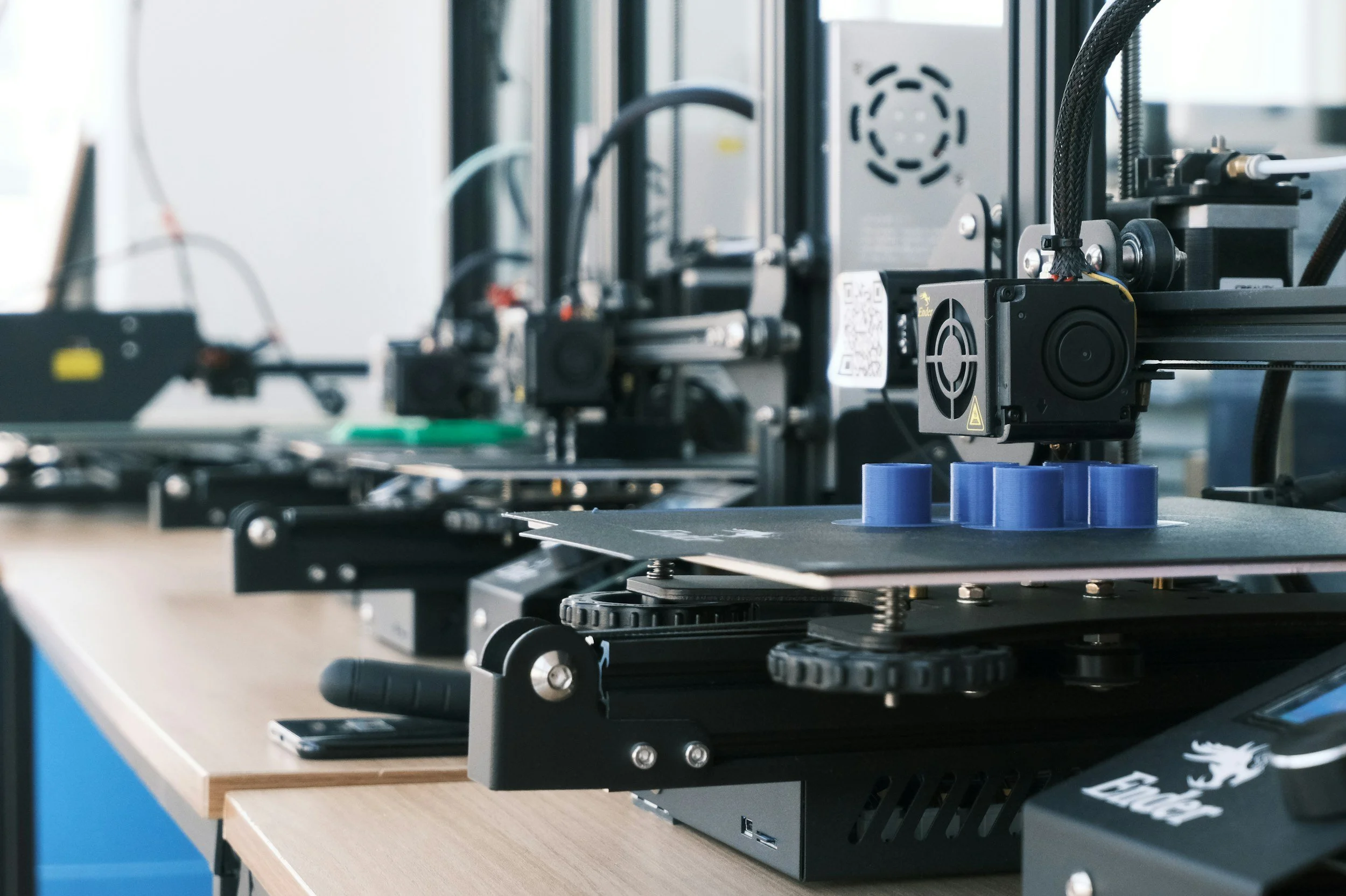

The Prototype

Upon approval of the rendering, we take the customization experience one step further by offering customers the option to receive a 3D printed prototype model of their jewelry design. This tangible prototype allows customers to see the design in physical form, providing a true sense of scale and detail. They can even try it on to ensure a perfect fit and feel. This stage bridges the gap between imagination and reality, empowering customers to make informed decisions before final production begins. It's another way we strive to exceed expectations and deliver an exceptional custom jewelry experience.

The Casting

After the customer approves the 3D printed prototype model, we proceed to the casting stage, a pivotal step in bringing their custom jewelry to life. Our casting process offers customers a wide array of options, including casting in all precious metals such as gold, silver, platinum, and more. Additionally, we have the capability to cast using clients' own metals, ensuring that their sentimental or unique materials are incorporated into the final piece.

During casting, the approved design is transformed from a resin model into a solid metal form. Our skilled craftsmen utilize the lost wax casting process which begins with the creation of a mold based on the approved prototype. This mold is made by encasing the resin prototype in a material that can withstand high temperatures, such as plaster or investment material. Once the mold is formed, it is heated to melt away the wax, leaving behind a cavity in the exact shape of the original design.

Next, molten metal is poured into the cavity, filling the space left by the melted resin-wax. The metal is allowed to cool and solidify, taking on the intricate details of the mold. Once cooled, the mold is broken away, revealing the newly cast metal piece.

The Finishing

After casting, our jewelry enters the finishing stage, where final details come to life. Skilled artisans meticulously polish the metal, enhancing its luster and detailing. Special finishes, like high-gloss or textured options, can be applied upon request. For designs that incorporate gemstones, the finishing process also includes stone setting. Our master stone setters delicately place each gemstone into its designated setting, ensuring a secure fit while maximizing the brilliance and sparkle of the stones.

Throughout the finishing process, our attention to detail is unwavering, ensuring that every facet of the jewelry is perfected to our exacting standards. The result is a custom masterpiece of artistry and craftsmanship, ready to be worn and cherished for a lifetime.